The hybrid car may be the latest thing in road transport, but hybrid ships that combine sail and steam were plying the oceans in the 19th century – and they’re set for a comeback.

Rolls Royce – better known for luxury cars and aero engines – is developing a ship that uses sails to cut emissions and soaring fuel costs.

Today, the shipping industry contributes almost 3% of global greenhouse gas (GHG) emissions, because of the dirty bunker fuel that powers most of the world’s ocean-going fleets.

A ship under development can carry 4500 tons fueled by an 180-foot sail and backed up by bio-methane engines.

“We’re at the dawn of a transition,” Oskar Levander, vice president for innovation at Rolls’s marine unit, tells Bloomberg. He predicts a switch from high-polluting bunker fuels to alternatives such as dimethyl ether and liquid natural gas, as well as “high-tech wind”.

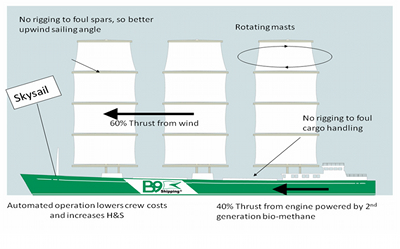

Rolls Royce is working with B9 Shipping, a Northern Ireland-based firm, on the hybrid ship, which will be 330-feet long and will be primarily powered by a Dyna-rig automated sail system.

The company says all the technologies needed are proven and readily available. The Dyna-rig sail system was originally conceived in the 1960s by German hydraulics engineer Wilhelm Prolls and was first used by Italian shipbuilder Perini Navi in its 289-foot clipper, The Maltese Falcon, which made its maiden voyage in 2006.

The free-standing and free-rotating system has no rigging and comprises numerous relatively small sails that are operated electronically from the bridge. This allows them to be trimmed quickly to maximize wind power and turned out of the wind in the event of sudden squalls.

Rolls Royce will provide a back-up power plant based on its Bergen model, which can burn methane produced from municipal waste by another unit of B9 Energy Group. The sail and engine can also be used together for optimal efficiency.

While the hybrid design increases upfront capital costs, B9 says the pay back is 3-5 years for a ship with a 30 year lifespan.

The shipping industry faces tighter controls on sulfur emissions from the International Maritime Organization. These require owners to use clean but more expensive grades of fuel. Trimmer designs and hybrid power systems offer a potential 55% efficiency gain, according to B9’s Diane Gilpin.

“Operational budgets are trumping build costs at the moment,” she says, adding that B9 is seeking £15 million ($22 million) to put a ship in the water within two years.

The cruise industry is notorious for its unregulated emissions and garbage disposal. Some like Norwegian Cruise Lines, which introduced carbon offsets last year, are trying to slowly change some business practices.